Electrical

VISION MT Technicians work with analog, digital and RF electronic devices as well as power and signal technology and enclosures for electronic sub-systems. We have multiple braiding machines on site to meet military requirements for ruggedization. Avionics aircraft assemblers are trained to read and interpret schematics, wiring and cable routing diagrams and blueprints. VISION artisans can assemble all types of electro-mechanical units and circuit boards, including standard, plexiboard, ceramic, thru-hole and surface-mounted, installation of active and passive components, forming and soldering parts, conformal coating masking , and assembly marking.

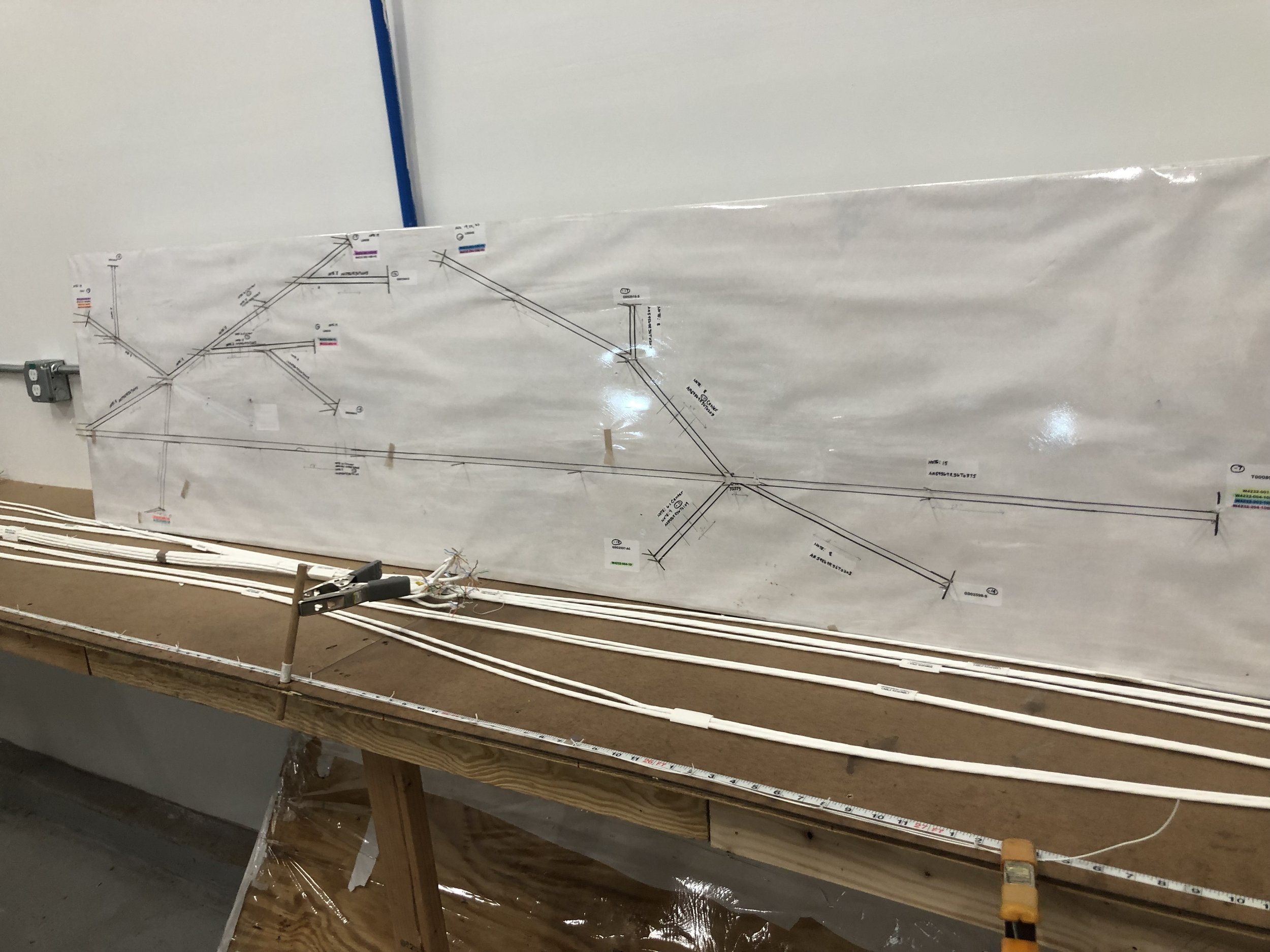

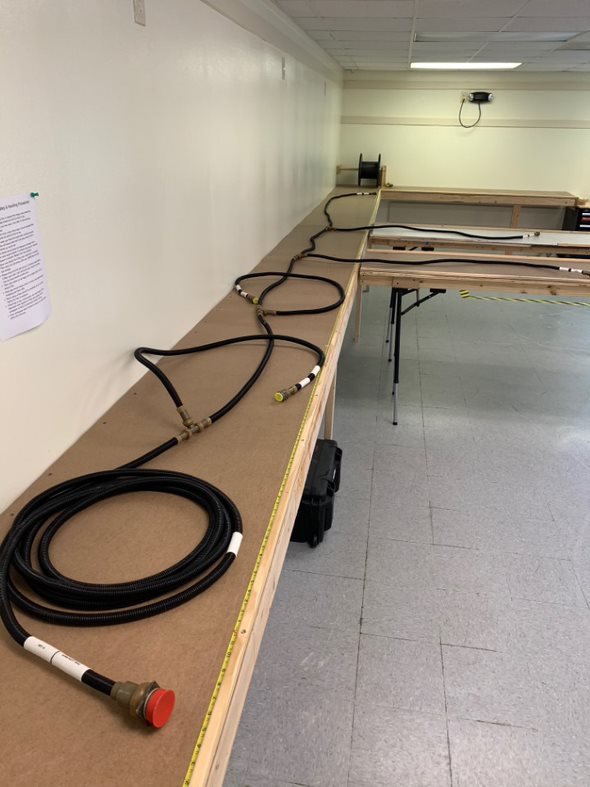

VISION MT electricians are highly skilled in cable assembly and harnesses fabrication as well as circuit card assemblies, panel and box wiring and fiber optics manufacturing. We build our own in-house harness boards to facilitate accuracy and maintain configuration control for production manufacturing.

VISION MT conducts continuity testing on integrated/wired assemblies ensuring proper buzz out and pin to pin connection prior to delivery.

Equipment includes:

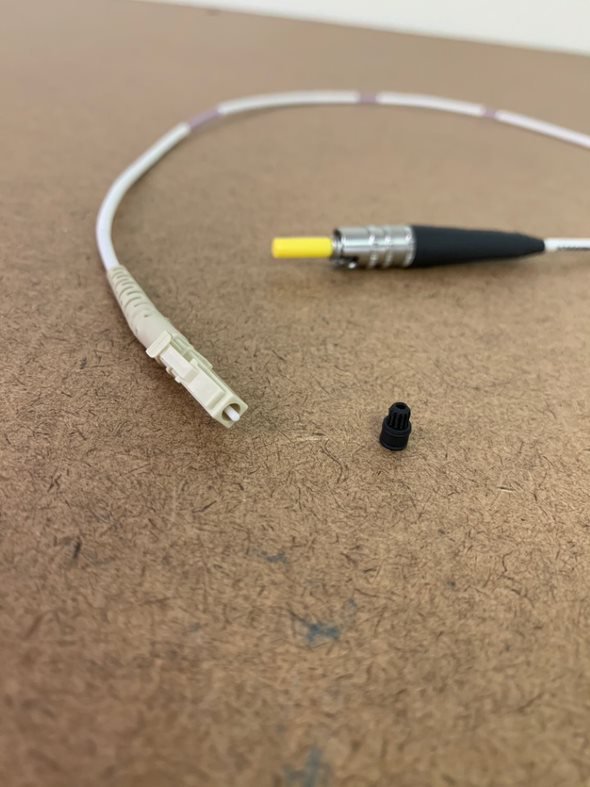

Aircraft and Shipboard Fiber Assemblies

Avionics/Electro-Mechanical Assemblies

Rapid Prototype Fabrication

Surge & Production Runs

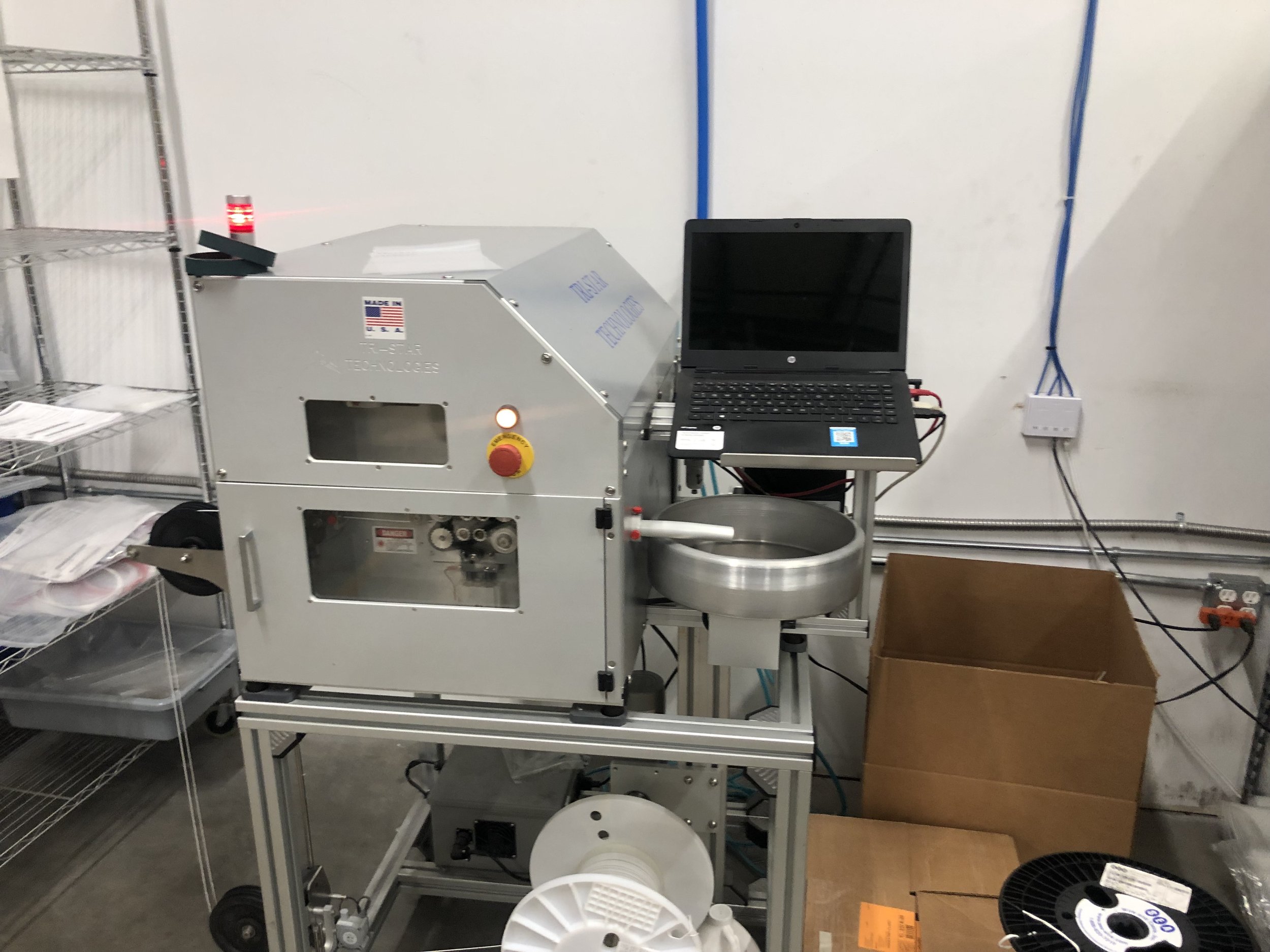

Laser Wire Marker/Cutting - M-100LFG TT Tabletop and Spectrum Nova 840i; complies with MIL5088I, AS50881, BAC5152, conforms to SAE ARP5607 (legibility)

Gladding Braiding machines (2) – 36 head and 24 head

Brady Printer BBP12 – markers, sleeves, shrinks and wraps

TE Printer

Pace/Weller temp controlled soldering stations

Temperature controlled heat guns

Insertion/Extraction tooling for contacts/pin crimping

Broad array connector tooling

Continuity Testers / Meters

Complex cable assemblies, wire harnesses, and coax cables.

EMI Shielded cables

A/C Installation & Mods